ABSTRACT

Transformer manufacturers can be faced with difficult decisions when it comes to large-scale investment. Uncertainty can delay large-scale investments resulting in equipment with older technology and inefficient work procedures being left in production. In this paper the authors expose a method where re-alignment of existing machines (through the integration of machine technologies such winding mandrels, wire flattening, cold welding, etc.…) can be done with incremental investment allowing companies to improve current processes while managing capital investment. The application of the Staged Investment method proposed in this paper can be adapted to other peripheral transformer component manufacturing lines such as cores or tanks with excellent results.

Index Terms—Transformer winding, Staged Investment.

I. NOMENCLATURE - DEFINITIONS

Transformer coil: High Voltage and Low Voltage conductive

parts of the transformer. Electrical energy is transferred

between them.

Staged Investment: gradual use of funds to implement

new technologies in a transformer manufacturing plant.

II. INTRODUCTION

The idea of intelligent and automatic machine operation

are broad concepts in transformer coil production. They can

mean different things to different people, depending on

their current level of technology. As part of this presentation,

MTM and H-J will present various modern concepts

associated with intelligent and automatic machine operation

that can be included in future machine considerations

by transformer manufacturers, regardless of their size and

the investment capacity. These concepts are applicable

when considering new machines but can also be applied

with respect to incremental improvements that can be

made to existing equipment. These features can have a

significant impact on the quality of the coil being produced

while improving equipment productivity.

This paper will illustrate the positive economic impact and

benefits of these concepts. Overall effects will vary depending

on the user. We encourage the reader to make his own

determination of real benefits based on the concepts

presented. Many of these solutions have been implemented

by transformer OEM’s globally, with a high degree of

success.

III. DEVELOPMENT OF THE CONCEPTS

Winding Machines can be divided into five classifications

of design:

- Low Voltage Foil

- High Voltage Foil

- Distribution Wire

- Power Wire

- Combined LV Foil and Wire

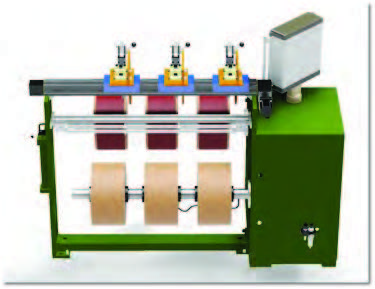

Pictures below illustrate the typical standard product lines

using some of these machine designs. Production capacity

in terms of number of units and kVA size determines type

and quantity of the winding machines. Fig. 1. Typical Low Voltage Foil Winding Machine.

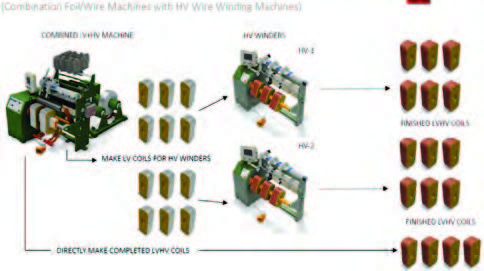

A. Combination of winding machines

Before making capital investments in separate HV and LV

winding lines, combined machines (designed to wind foils

and rectangular or round wires in the same machines) can be

a good solution to save time and investment capital with

production requirements are small. The addition of wire

winding to a foil-winding machine are small when considering

the price of a separate wire winding machine. Many

“state of the art” features are present in this first step to the

Intelligent Manufacturing Line:

The cost of adding HV wire feature to a LV winding machine is

less than 40% of adding a new HV winding machine to the

production line (cost dependent on the number / type of

wires)

- Wires are guided onto the coils by PLC based automatic

control systems, eliminating manual control of tension by

the operator. This adds important quality value to the winding

mainly to get the standard damage curve requirements

per IEEE C57.109 for short circuit withstand capacity.

- Likewise, the coils are guided through the machine with

automatic alignment and tension control. It improves the

short circuit capacity by making easier the alignment of the

HV and LV windings.

- Machine’s PLC ensures the winding is done to program. No

need to make further tests on turns ratio. This saves time and

allows operator to concentrate in primary processes building

quality into the process.

- In these machines, as in any last generation winding

machines, the operator faces front to the coil being wound,

with insulation, foils and wires feeding from the back of the

machine. This way the winding operator controls easier

quality facts like windings alignment and the need to refill

any material as he is positioned in front of the pay offs.

- Production time is reduced through elimination of transport

of the LV coil to the HV winding machine since the HV coil is

applied to the LV winding in the same machine. Combined

winding machines reduce production time up to 30%.

-

Combined machines reduce the number of windings

flowing in production (from 2 pieces to 1) which is part of the

lean manufacturing concept to reduce work in process (WIP).

Less time is used to handle the coils, stage the coils between

operations, which reduces handling and the potential of

damage.

The features integrated into these machines can be standard

or advanced. To begin with our incremental improvements

method, a standard machine can be introduced using only

single HV and LV coils winding systems and leaving

multi-winding systems for further incremental steps. See B.

below. However, combined machines can gain complexity

including multi-coil winding systems. Figure 4 shows a

typical layout of a large combined machine for large distribution or small power transformers using 2 parallel foils and up

to 6 rectangular wires.

B. Multi-coil production systems and setup of production

cells in manufacturing

Once the volume of production increases, it gets convenient

to move to our second incremental improvement: the

multi-coil production concept and introduction of the

production cells. This method takes into consideration the

balancing of time to make LV vs. HV sections of the coil. This

is a scaling up concept that builds on the idea of having a

combination machine.

Multiple coil machines are very useful mainly for HV coils

due to the fact production time for HV coils may be 3 or 4

times the production time of LV coils (in some cases). Initially

the machine may take a little longer set-up time, but once in

operation, every turn of the machine will produce multiple

coils. This results in production time per coil being reduced

by about 1 divided by the number of coils mainly in small

kVA rating transformers where the number of turns is high.

Advantages are evident in the productivity of the process and

the use of less machines for the same production volume.

Typical reduction of production times when using triple HV

winding machines is up to 60%, again a function of number

of turns: the larger it is, the higher the productivity gains.

The production cell concept provides a method for balancing

HV and LV coil production, which is a challenge due to the

time differential in production of the two. This concept

consists of combining HV winding machines with compact or

combined HV/LV winding machines to achieve continuous

production of both windings. While the combined machine

produces many LV coils to feed the HV winders, it can also

produce complete (HV plus LV) coils. Production of the LV

coils can be scaled with production of the complete HV/LV

coils in order to provide a balance in production of the coils,

thus generating uninterrupted supply of both. Not having

idle time easily reduces 20% of the total windings production

time per day.

Data from each machine or group of machines can be collected

and downloaded to a central location for analysis of the

production flow.

Insight to the Production Process can be determined:

- Costing of each coil

- Trending in processes

- Bottle necks in the production process

- WIP management

- Variations in operator and machine performance

C. Automatic insulation cutting and tensioning systems

With older winding machines (without re-alignment) it can

be difficult to control tension between HV layers of the coil.

With LV coils “manual” or “non-uniform” tension is provided

resulting in loose coils with poor short circuit strength. With

newer machines insulation papers are tensioned and

positioned near the coil so the operator can gain access

during the winding. Uniform tension is applied. Machines

can be equipped with an automatic cutting process of the

insulation paper further speeding up the production

process.

As the next incremental system improvement, insulation

tensioning systems improve short circuit strength to the coil

assembly for a relatively low investment. Figures below

illustrate typical paper tensioning systems. Note that the

papers are tensioned equally across coils on the machine,

insuring equal tension within each coil. It must be reminded

short circuits are main failure cause for distribution transformers.

D. Closed Loop Wire Tensioning Systems

With older winding machines (without re-alignment) it is

common for round wire tension to be controlled with a

mechanical brake (and possibly other mechanical systems).

While this system provides tension to the wire, it is up to the

machine operator to determine if the tension is correct. This

is done by qualitative methods. With a closed loop tensioning

system the designer will be able set the required tension

range for a given conductor and the PLC system will maintain

the tension through the coil winding. This is an advanced

feature available on new winding machines. Keeping

constant the wire tension at a certain value, adds uniformity

to all manufactured windings assuring short circuit

withstand ability to the transformer.

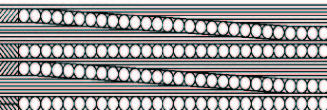

E. The gradient insulation system, also known as

progressive insulation

The gradient insulation system employs the use of a continuous

insulation strip to vary the thickness of the insulation

across the winding layer according to the program.

This method allows the appropriate insulation thickness to

be used where there is greatest difference in voltage potential,

and less thickness where there is less potential. The net

result is a reduction in coil diameter, with corresponding

reduction in the amount (mass) of insulation used. Figures below show the Gradient Wrapping representation. Total

winding material savings (conductor plus insulation)

arounds 15%. Also, because the insulation layer is being

wound at the same time as the wire section, the time to wind

the HV section can decrease by as much as 30%.

This improvement is of great benefit to manufacturers using

windings with gradual or reduced insulation mainly for

grounded wye connection of power transformers.

F. Wire flattening – 1 or 2 wires:

Round wire flattening is a well-known process providing

important benefits in HV coil designs for distribution transformers

such as:

- Reduction in air gap between turns, improving the space

factor. This causes a reduction of the core window, reducing

core losses.

- Reduces the electrical stress between layers by reducing the

number of turns per layer. In some cases, reduction of the

insulation thickness can be achieved.

- Substantially increases the surface of the conductor in

contact with the insulation paper, thus increasing the short

circuit strength by improving the adherence between layers.

- Reduction of the radial coil build by reducing the wire thickness

by up to 20%. This means narrower core windows, less

materials and losses. Total cost reduction between 5 to 10%

can be reached by adding wire flatteners to the coil winding

production line.

Wire flatteners can be added to existing machines.

G. Cold Welding:

Cold welding of conductors, leads and terminals was developed

to eliminate the need for heating of conductors either

to join two conductor spools or to join conductors and terminals.

In many cases this can require joints of different materials.

Cold welding allows joins between copper to copper,

copper to aluminum or aluminum to aluminum.

This incremental investment can reduce production time;

however, its main impact is in the quality and long-term

duration of the joins as e.g. many of the copper-aluminum

joins are affected with the pass of the time by galvanic

reactions in the contact areas creating hot spots that reduce

transformer’s life.

The process is clean, quick, requires no cooling time, and can

be added to existing machines. This process can also be

provided by a stand-alone machine that is portable for transport

between work centers. Cold Welding systems can be an

integrated foil and lead cleaning system and vacuum for

removal of debris. Design parameters for the cold-welding

process can be computer controlled and integrated with the

winding process.

H. Winding Mandrels and Forms:

Rectangular, oval and round expanding mandrels are necessary

tools to produce compact coils for distribution and

power transformers. Cost of these tools varies as a function of

the transformer size. In general, the investment required

increases exponentially with the kVA size of the transformers.

Pneumatic or mechanically expanding versions are

available. Quality mandrels keep windings alignment and

tension helping to maintain transformer damage curve and

winding dimensions within tolerance. It should be noted

that rectangular mandrels can be designed with 2 or 4 way

expansion (independent).

IV. CONCLUSIONS

The methodology developed in this analysis illustrates how

transformer manufacturers can employ the Staged Investment

process to gradually implement Intelligent Automatic

Transformer Coil Manufacturing Lines.

For those cases where manufacturers have low investment

capacity, the proposed method of investment allows the

manufacturer to start a plan with periodic investments that

finally takes him to a completely automated production line

gradually reducing costs and improving quality.

By using these methods and according to the experience of

the authors, high tech production can be achieved by small

or large manufacturers at their own pace of investment.

V. REFERENCES

L. Wang, S. Wang “Is staged financing designed for alleviating

risks or agency problems?” in Handbook of Business and

Finance. Nova Science Publishers, 2009, ISBN

978-1-60692-855-4

VI. BIOGRAPHIES

Orlando Giraldo was born in Pereira Colombia, on Feb 3,

1953. He graduated from the Technological University of

Pereira. His employment experience included 13 years at the

ABB Distribution Transformers Plant in Pereira and 13 years

at the SIEMENS Distribution and Power Transformer Plant in

Bogota Colombia. Fields of experience include design,

production, tests and sales. He has also worked for many

years in the Transformer Standards area in Colombia. He has

been teacher of Electrical Machines at the Technological

University of Pereira and at the National University of Colombia

in Bogota. He is since 1999 with The H-J Family of

Companies; currently Senior Consulting Engineer.

Gord Atamanchuk, P.Eng. has worked in various positions

in machine development, manufacturing, and sales since

graduating from the University of Manitoba with a Bachelor

of Science in Mechanical Engineering in 2000. Gord’s

involvement in product design, testing, manufacturing, and

service / support gives him unique expertise on the machine

development process and the role technology plays in this

environment. Gord is currently General Manager of Micro

Tool & Machine Ltd. (MTM), an engineering firm specializing

in custom machine design and automation to support

various industries (including the transformer industry).

Download Resource